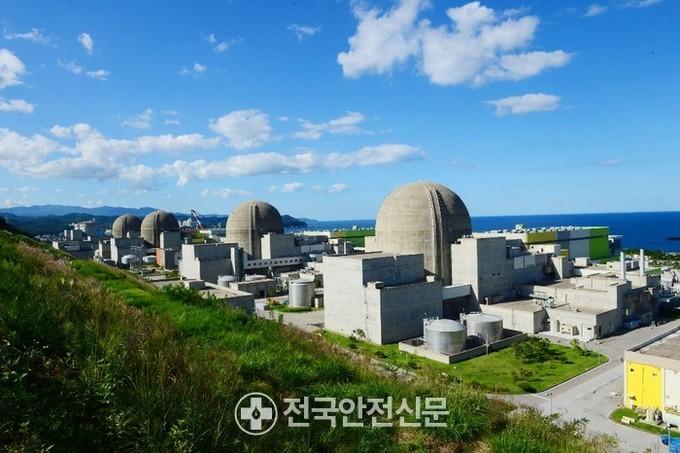

एक A view of second and third rounds of Hanul Nuclear Power Plant © Editorial Department |

Hanuwon Co., Ltd. Hanul Nuclear Power HQ said, “On February 25 (Thursday), Hanul Unit 4 (pressurized light water reactor type, 1 million kW) turbine protection system’s electric bypass valve closed. It announced that it resumed power generation on Friday 26 February at 1:44 pm.

In this regard, the Civil Environment Monitoring Organization of Hanul Nuclear Power Plant announced the survey data on “Summary of Suspension of Hanul Nuclear Power Plant” through its website. According to the monitoring agency, The reason for the suspension of power output was found to be “valve operation failure due to (approximate) foreign case of electric bypass valve”. Following are the data of the survey revealed by the Hanul Nuclear Power Plant Environmental Monitoring Organization.

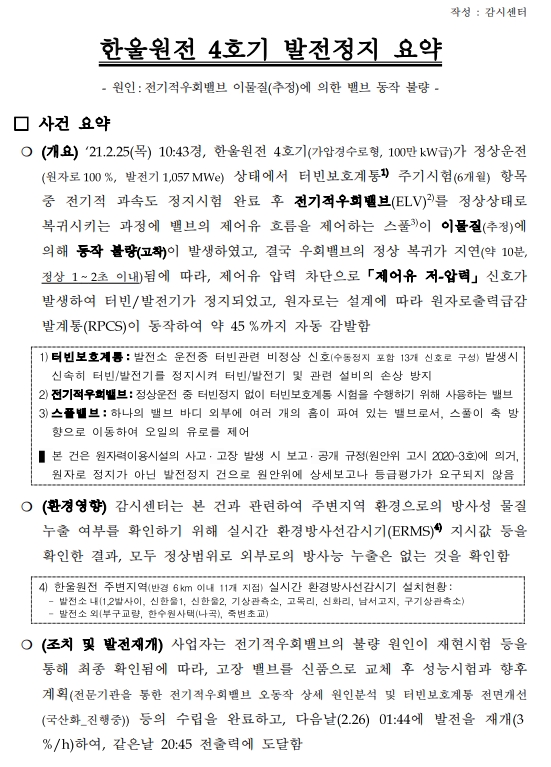

– Summary of Hansuwon Hanul Nuclear Power Plant Unit 4 Suspension

-Cause: Valve malfunction due to (approximate) foreign case of electrical bypass valve.

Summary Incident Summary

25 (overview) On February 25, around 10:43, ’21 (Thursday), Hanul Nuclear Power Plant 4 (pressurized light water reactor type, 1 million kW class) operates normally(100% reactor, 1,057 MWe generator) Turbine protection system 1) Periodic test (6 months)After completing the electric overspeed stop test, return the electric bypass valve (ELV) 2 to the normal position. In the process of returning, the spool 3) controls the flow of control oil of the valve Because of this there was a glitch (sticking),

Eventually, the normal return of the bypass valve is delayed (about 10 minutes, Usually within 1 to 2 seconds), the “ control oil low pressure ” signal is displayed by turning off the control oil pressure. Happened and the turbine / generator was shut down, and the reactor output rapidly decreased according to the design of the reactor.The foot system (RPCS) operates and is automatically reduced by approximately 45%

1) Turbine protection system: when abnormal signals related to turbines (composed of 13 signals including manual stops) occur during the operation of the power plant Turn off the turbine / generator immediately to prevent damage to the turbine / generator and related facilities

2) Electric bypass valve: A valve is used to perform a turbine safety system test during normal operation without stopping the turbine. 3) Spool valve: As a valve with multiple grooves outside a valve body, the spool is in the axial direction.Going out in the sun controls the oil flow route

Losure This case is in accordance with reporting and disclosure rules in the case of accidents or breakdowns in nuclear power facilities (notice number 2020-3 of the Korean National Security Agency), No detailed report or rating evaluation is required on the original bill as it is a power plant suspension other than a nuclear reactor suspension.

❍ (environmental impact) in this case, monitoring center Real-time environmental radiation monitoring (ERMS) 4) Signal values, etc. As a result of the investigation, it was confirmed that they are all within normal limits and there is no leakage of radioactivity to the outside.

4) Installation status of real-time environmental radiation in the vicinity of Hanul Nuclear Power Plant (11 points within a radius of 6 km):

Within the power plant (between 1 and 2, Shin Hanul 1, Shin Hanul 2, Meteorological Station, Gomok-Ri, Shinhwa-Ri, Southwest Hill, Gugi-Song Observation Station) Compared to the power plant (Bugu Bridge, Hansuwon House (Nagok), Zookebon Elementary School)

And (power generation measures and revitalization) businesses should conduct reproducible testing, etc. due to the failure of the electric bypass valve. As it was finally confirmed through, replacing the faulty valve with a new one, performance testing and future to plan[전문기관을 통한 전기적우회밸브 오동작 상세 원인분석 및 터빈보호계통 전면개선(국산화_진행중)] The installation of the lamp was completed, and development resumed the next day (2.24) (3) at 3:47 pm.% / h), reaching full power at 20:45 on the same day

Written by: monitoring center /

Data = provided by Hanulwon Civil Environmental Monitoring Organization

4 KHNP Hanul Nuclear Power Plant Unit 4 Power Generation Suspension Summary-Cause: Valve malfunction due to (approximate) foreign case of electric bypass valve.Data = provided by Hanulwon Civil Environmental Monitoring Organization © |